Authored by: Nikita Ambasana, Customer Success Manager

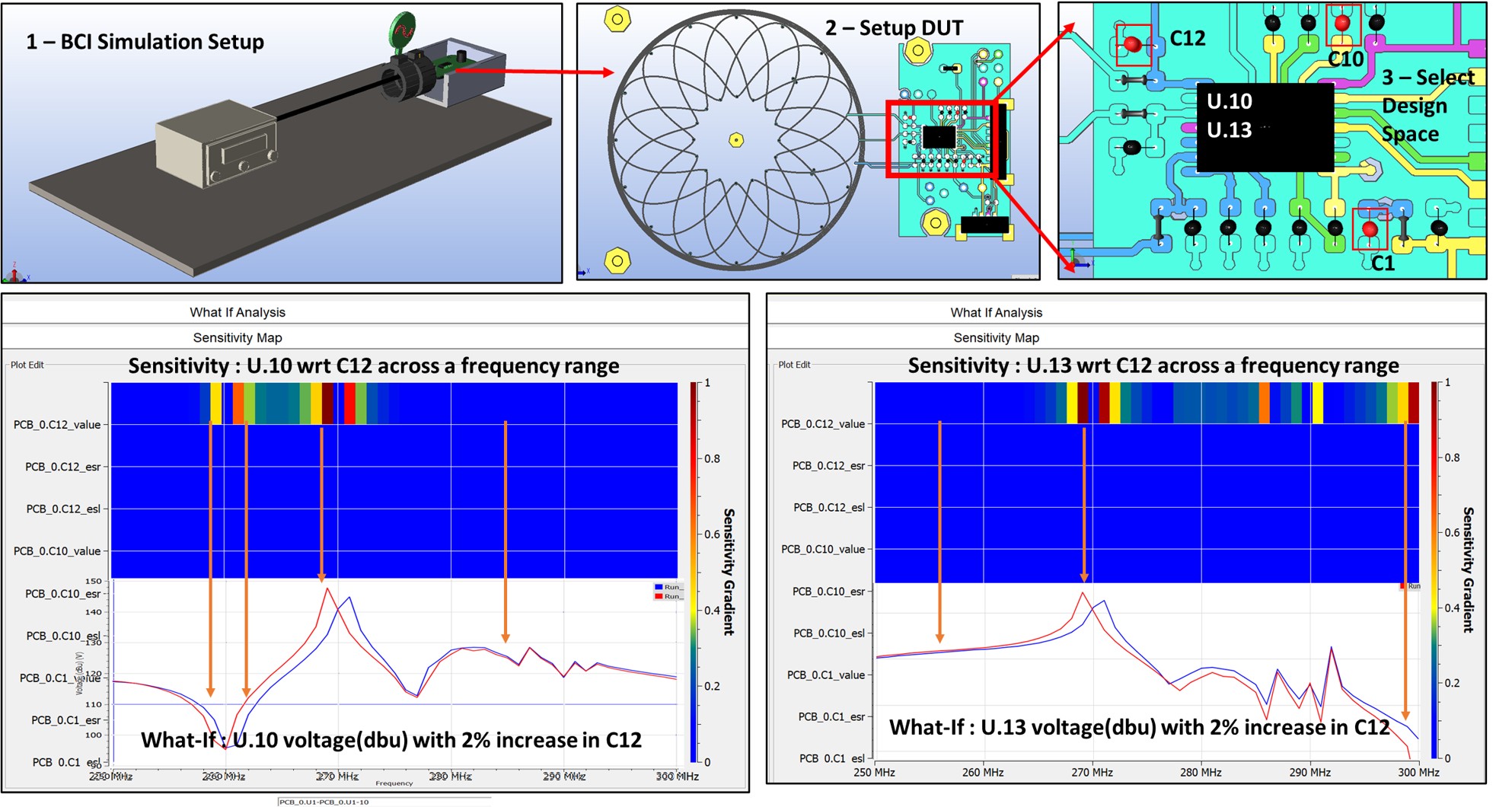

Compliance-Scope’s BCI Lab streamlines EMC optimization with two complementary tools: Sensitivity Analysis and What-if Analysis. Together, they identify critical components and validate design changes quickly, minimizing costly iterations.

Sensitivity Analysis – Quantify Component Impact

- Select up to 10 components (R, L, C) for evaluation.

Sensitivity defined as:

where (y) = observed output (e.g., IC pin voltage) and (x) = component parameter.

What-if Analysis – Fast Design Exploration

Modify component values (e.g., +20% capacitance) and see EMC impact in seconds: No assumptions or approximations

Model-based approach: No need to re-run full 3D simulations.

Supports single and multi-pin modifications.

Results can be overlaid for direct scenario comparison.

Integrated Workflow

Sensitivity Analysis → Identify critical components and failure regions.

What-if Analysis → Validate modifications and converge on optimal values rapidly.

Result: A rigorous yet agile workflow that reduces design cycles, conserves simulation resources, and accelerates EMC compliance.

© 2025 SimYog Technologies Pvt. Ltd. – All Rights Reserved.