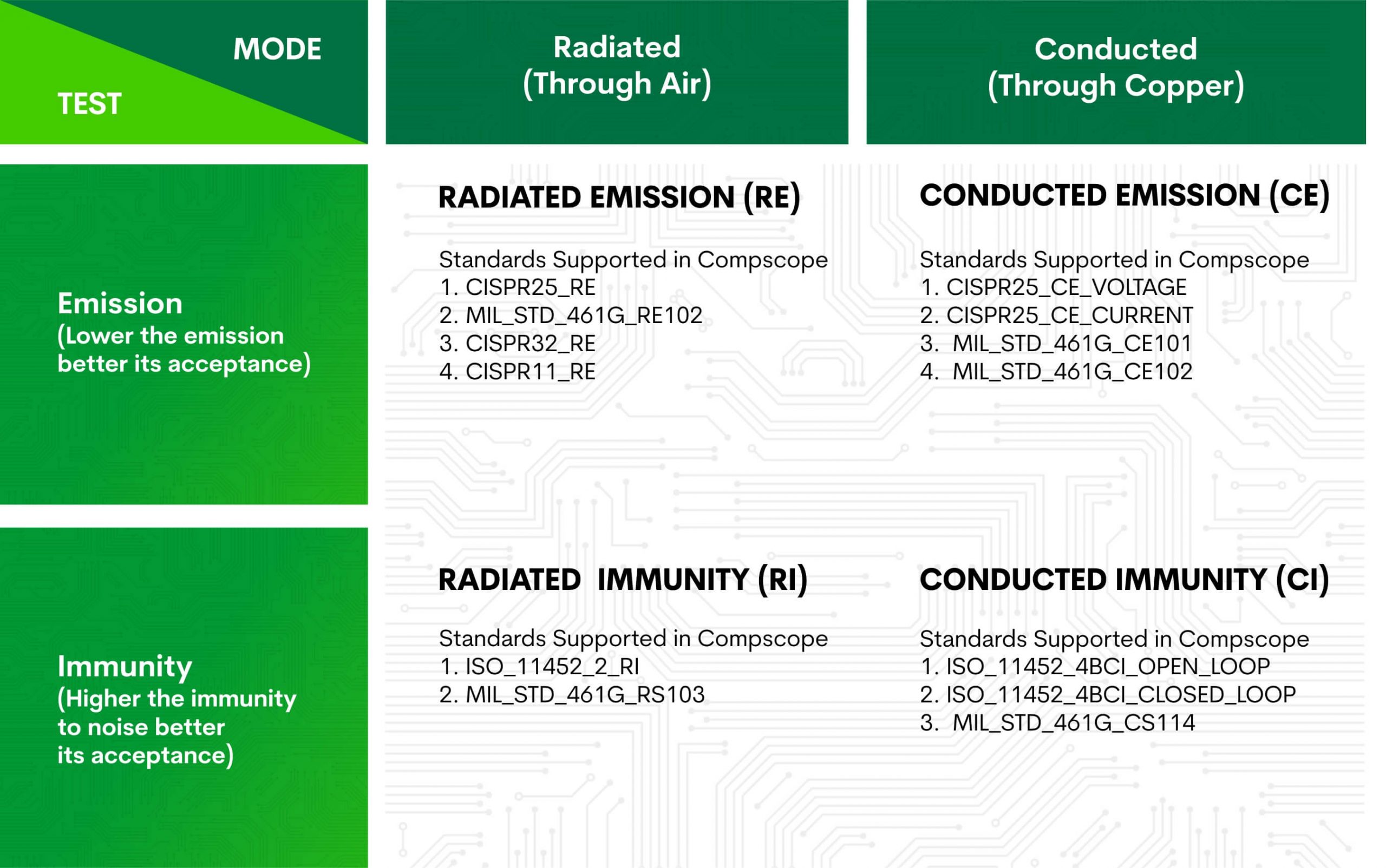

COMPLIANCES THAT WE SUPPORT

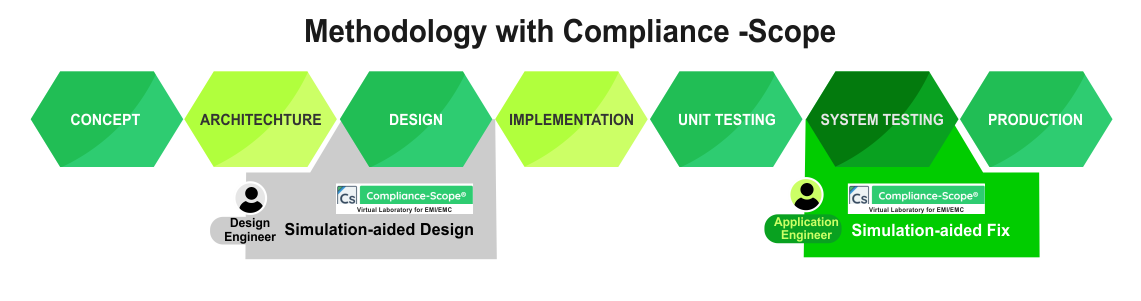

Compliance-Scope® is built such that the user can instantiate a laboratory with a chosen EMI / EMC standard on the click of a button. After opening the laboratory. the user can configue the setup using utilities to suit the current experiment.

Current Injection

The Current Injection (CI) method is mainly used for RF immunity testing of automotive components and ICs in electronics industry. In this test method , current is injected on one or more pins simultaneously to test for malfunctions.

CI

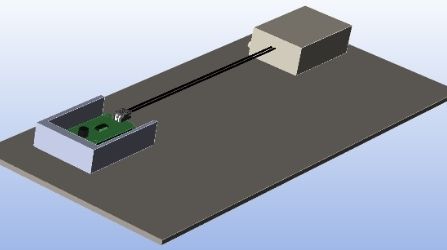

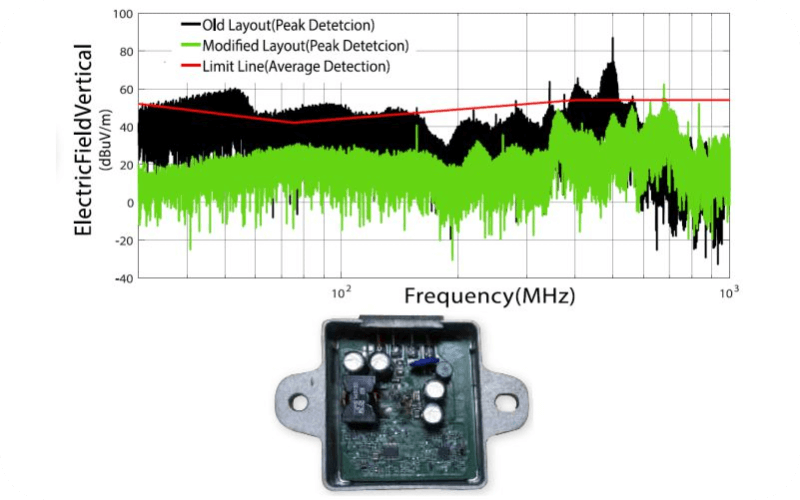

Radiated Emissions

Radiated emissions testing involves measuring the electromagnetic field strength of the emissions that are unintentionally generated by the device. Emissions are inherent to the switching voltages and currents in the device.

RE

Conducted Emission

Conducted emission is to find out the radio frequency noise present in the physical wiring or traces of an electrical system due to any switching or harmonic resonances within a equipment.

CE

Radiated Immunity

Radiated immunity test is to measure the immunity of device when subject to prescribed radiated electromagnetic field.

RI

USERS OF COMPLIANCE SCOPE®

Semiconductor

Debug Customer Hardware

EMC - Resilient ICs By Design

Tier - 1

Pass Compliance

Design For EMC